A team of researchers at the University of California San Diego has unveiled a deceptively simple but powerful way to measure lithium metal battery performance using a tool already standard in battery labs: scanning electron microscopy (SEM).

This innovation could accelerate the race toward safer, longer-lasting, and higher-capacity batteries the kind that could double the driving range of electric vehicles and dramatically extend the battery life of portable electronics. The work was recently published in Proceedings of the National Academy of Sciences.

Lithium metal batteries can store twice the energy of conventional lithium-ion cells. But the promise comes with a problem: controlling lithium morphology , the way lithium deposits form during charging and discharging. Smooth, even deposits mean longer life. Uneven deposits can form dangerous needle-like structures called dendrites, which can short-circuit a battery.

Traditionally, researchers have judged deposition quality by visually inspecting SEM images. But that process is subjective with scientists using inconsistent terms like “mossy,” “chunky,” or “globular” to describe the same structures.

Lead author Jenny Nicolas, a Ph.D. candidate in materials science and engineering, and her colleagues in Professor Ping Liu’s lab decided to change that. They developed a free, open-source algorithm that turns SEM images into hard numbers.

So how does it work?

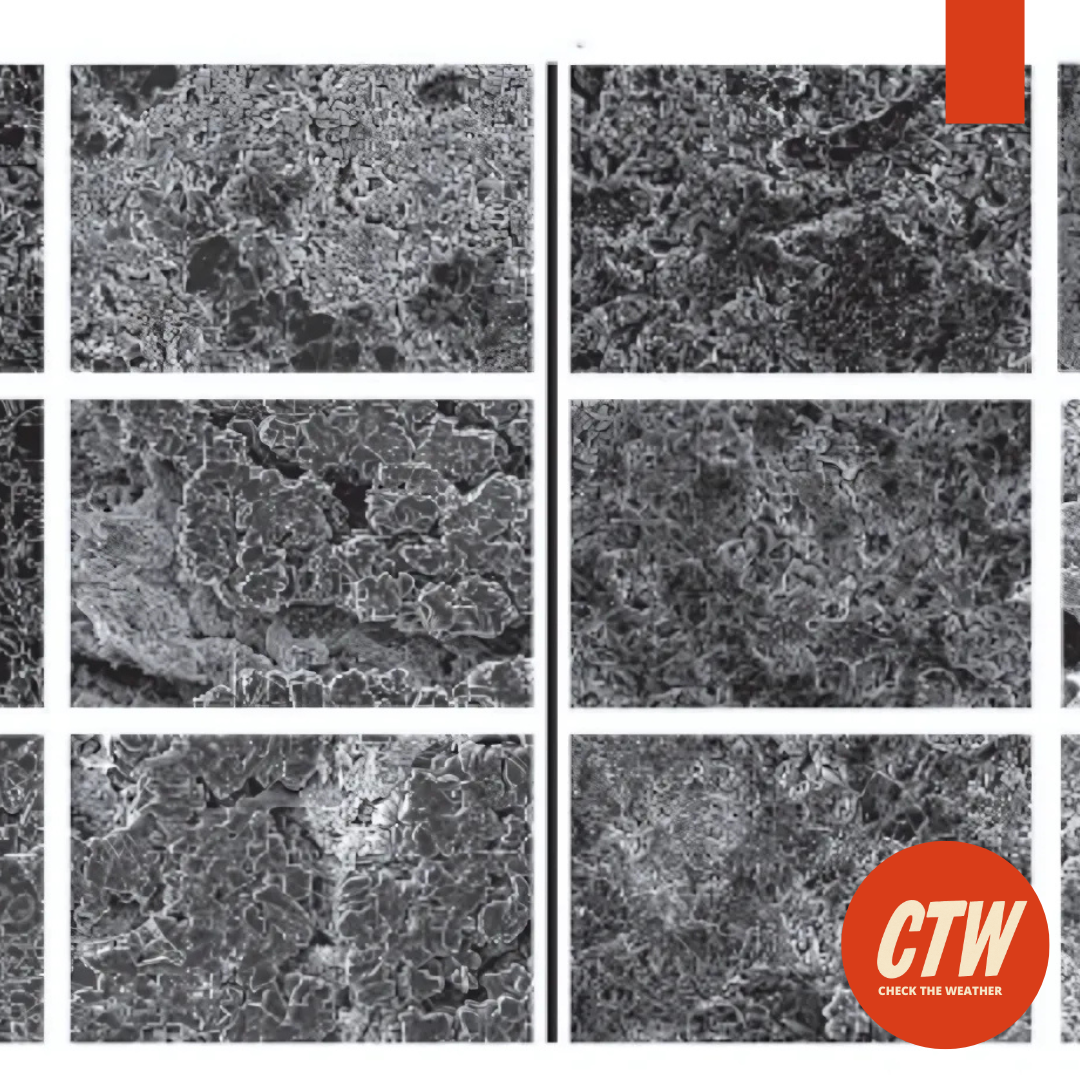

First, the team takes scanning electron microscope images and turns them into crisp black-and-white pixel maps. In these maps, white areas show where lithium has settled, while black areas mark the bare electrode surface. The software then slices the image into smaller chunks, checks how much white shows up in each one, and uses that to figure out the index of dispersion essentially, a score for how evenly the lithium is spread out.

A low score means the deposits are smooth and uniform. A high score means the lithium is clustering a red flag for trouble ahead.

The team tested their method on 2,048 synthetic images with known patterns, confirming its accuracy. Applying the tool to real batteries revealed that lithium deposition becomes less uniform over time with sudden spikes in ID often signaling battery failure before it happens. That makes it not just a measurement tool, but a potential early warning system.

Because SEM imaging is already routine in battery research, this method can be adopted immediately no expensive new equipment required. As Nicolas put it, it’s “low-hanging fruit” for better, faster battery analysis.

Read more here–